MERGER FERRI – DIAMANTEK

Due to the merger by absorption between INDUSTRIAS FERRI, SA (absorbing company) and DIAMANTEK SYSTEMS, SA (absorbed company), all interested parties are hereby notified of the right of the shareholders of the absorbing company and the creditors of the companies participating in the merger to examine at the registered office the joint project and the annual accounts and management reports for the last three financial years, as well as the reports of the corresponding auditors of the companies where they are legally required and, where applicable, the directors’ reports, the reports of independent experts, or the merger balance sheets when they are different from the last approved balance sheet, or, in the case of a listed company, the half-yearly financial report, as well as to obtain, where not published on the website, the free delivery or mailing of the full text thereof.

Gondomar, July 21, 2025

The sole director

Patricio Fernández Goberna

Ferri signs new contract with Dutch shipyard Damen

Ferri wins a contract with Damen to equip the deck of its next oceanographic vessel. The agreement consolidates Ferri as a reference supplier for the Dutch shipyard and confirms its leadership in the design, development, manufacture, assembly and maintenance of deck machinery for large vessels.

The Damen Group is a world reference in shipbuilding. It is active in 36 shipyards specialising in military vessels, mega-yachts, oil support vessels, towing vessels, oceanographic vessels and other highly sophisticated vessels. With more than 12,000 employees, it operates in more than 100 countries and has an annual production capacity of 180 vessels. More than 6,500 vessels delivered over almost a century of existence endorse the trajectory of a company known for its high quality standards. This letter of introduction highlights the value of the contract signed by Damen with Industrias Ferri to equip all the deck machinery for its new oceanographic vessel.

This agreement confirms the satisfaction of the Dutch company with the work carried out by Ferri in its previous contract, for which it supplied 29 machines worth more than three million euros for a 74-metre fishing vessel. The equipment included all the scientific, fishing and manoeuvring machinery, as well as the gantries, cranes, davits, mooring and anchoring system, and all the controls, panels and automatic devices. This new contract consolidates Ferri within the portfolio of preferred suppliers of the Dutch giant, with which it is also working on several projects for military vessels and mega-yachts.

“We are the only company in the world with 100% in-house technology for all deck machinery and its controls,” explains Patricio Fernández Goberna, general manager of Industrias Ferri. “This condition allows the shipyard to improve the construction process and guarantees a perfect adaptation of the machines and their operation for both the shipowner and the operator. We reduce the processes and improve the whole process of the life cycle of the machinery; its adaptations, its maintenance, even its possible modernisations”.

Integral service

The contract signed with the Damen shipyard confirms the good acceptance of Industrias Ferri’s comprehensive service in the international market. The Galician company created its Ferri Systems division in 2018 for the development of technologies in drives and controls, a department that today has more than 30 employees, including 20 of the nearly 50 engineers working at Ferri. “We have an impressive team. Ferri Systems has a specially qualified staff for the drives of machines using variable frequency drives and their control via PLCs. We have programmers for all brands and we have qualified personnel for their design and manufacture”.

The integral service provided by Ferri, Ferri Systems and Talleres Carral allows the Galician group to respond with agility and efficiency to the most sophisticated projects and to operate among the international elite in the design, development and implementation of deck machinery. “It is a source of pride to be able to export Spanish technology to the most advanced ships in the world,” concludes Fernández Goberna.

Ferri guarantees the safety of offshore wind farm technicians

The most important offshore wind farms in Northern Europe once again rely on Ferri for the development of sophisticated equipment for the transfer of offshore technicians. The French shipowner Louis Dreyfus Armateurs equips its last two vessels with the revolutionary davit developed by the Galician company.

The harsh conditions in which offshore wind farms operate prove the ability of manufacturers to develop efficient working devices in such a hostile environment. One of the biggest challenges is the transport and transfer of technicians to the wind turbines, an operation that is very sensitive to sea conditions and where Ferri has designed and manufactured specific equipment that minimizes risks by absorbing the movements of the ship and the vessel that floats and recovers. This dynamic compensation mechanism has become a safety benchmark for the transfer of people at sea.

The effectiveness of the device convinced the prestigious French ship-owner Louis Dreyfus Armateurs to contract Ferri to develop, manufacture and install a tailor-made davit on the Wind of Change, an 84-meter multipurpose vessel that operates in partnership with the Danish wind energy specialist Ørsted. The main purpose of the Ferri davit is the launching and recovery system of a service vessel for wind farms and weighing up to 12 tons.

After successfully completing the installation of the davit on the Wind of Change, Ferri has signed on for the development of new equipment for Louis Dreyfus Armateurs’ second ocean wind farm support vessel, the Wind of Hope.

The Ferri folding gangway convinces shipowner Mystic Cruises

The folding gangway developed by Industrias Ferri has become an indispensable accessory for the new luxury ocean expedition cruise ships of the shipowner Mystic Cruises.

The World Voyager, owned by Mystic Cruises, is the first ship to install the folding gangway developed by Industrias Ferri. The World Voyager is a 126-metre long hybrid propulsion ship belonging to the Portuguese shipowner’s series of luxury ocean expedition cruisers.

The Ferri folding gangway operates sequentially and fully automatically, managed by a programme that performs the functions of unlocking, opening the door and unfolding the gangway, although it can be operated manually depending on the needs of the service. Its attractions include its compactness, as all the hydraulic, electrical and mechanical mechanisms for a 9-metre gangway are concentrated in less than 10 cubic metres, weighing barely 3,500 kg, which means it can be installed in a very small space.

The Ferri folding gangway is designed for loading and unloading passengers, meets the highest safety standards (certified by Bureau Veritas) and is equipped with a freefloat system (adjusting to height variations when supported in port) and safety gear (locking under sudden movements). Its high mobility allows turning angles of up to 80 degrees, and can position itself practically parallel to the ship if circumstances require it.

The satisfaction of the shipowner with this bespoke naval engineering project has led to Industrias Ferri adding a second unit in the World Navigator, the twin of World Voyager, and to agree to manufacturing 2 more gangways for the next 2 Mystic Cruises oceanic cruises.

SEALAB PROJECT USV

LAUNCH OF THE SECOND USV

Chaired by the Second Vice-President and Regional Minister of Economy, Business and Innovation of the Xunta de Galicia Mr. Francisco Conde, Industrias FERRI has launched its second USV.

This drone, built within the SEALAB project (a project financed by GAIN within the CONECTE PEME 2018 program with FEDER Funds 2014-2020) is intended to take water samples to study its degree of contamination.

Please click on the following link to see the news broadcast on TVG: USV LAUNCH

GLOBAL COMPANY

Industrias FERRI has achieved in this year 2020 the accreditation as a GLOBAL COMPANY granted by the VIGO FREE ZONE to those companies that present high values in magnitudes directly related to the internationalization process, such as the number of foreign clients, number of countries to which who exports, volume of exports outside the EU, establishments abroad and personnel dedicated to internationalization tasks.

CIRCULAR COMPANY

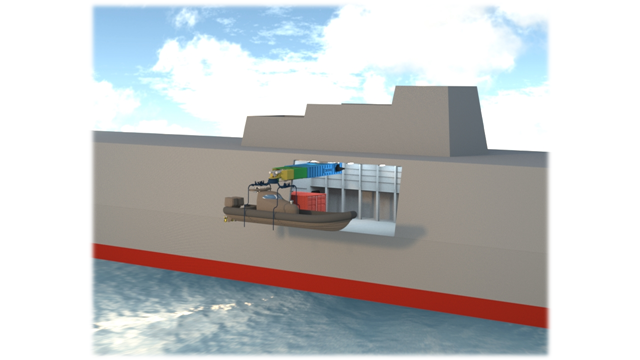

LARS FOR MULTIMISSION SPACE

IN INDUSTRIAS FERRI HAVE DEVELOPED A LOAD HANDLING SYSTEM IN MULTIMISSION SPACES DESIGNED FOR THE NEW SPANISH FRIGATES OF THE F110 PROGRAM IN ACCORDANCE WITH THOSE REQUESTED BY THE SPANISH NAVY

In accordance with the requirements of the Spanish Navy, this system must be capable of loading cargo from land with sizes such as a 40 foot container (limited in weight to 15 tons) or a vessel up to 12 meters in length. In some Sometimes the loads to be shipped are delicate and their handling must consider this aspect.

Likewise, you must move loads within the space in such a way that the capacity of the space to accommodate the greater number of components and move the loads towards the flight deck so that they can be loaded or transported via helicopter or unloaded from the deck itself with means other than the ship itself.

Finally, it will have to put in the water and recover certain loads that require it, such as boats or both surface and unmanned submarine vehicles.

Please click in the link to read more infodefensa.com

INDUSTRIAS FERRI & ESCRIBANO MECHANICAL & ENGINEERING

IT HAVE BEEN TAKEN PLACE THE SEA TRIALS IN WHICH AT THE FIRST MARINE DRONE DEVELOPED IN SPAIN IN 2016 BY INDUSTRIAS FERRI, CALLED USV VICTORIA, IT WAS INTEGRATED THE NEW REMOTE EMPLOYMENT WEAPONS STATION FOR NAVAL AND LAND APPLICATIONS, CALLED ASPIS, AND THE OTEOS SYSTEM, BOTH OF OUR PARTNER IN THE PROJECT ESCRIBANO M&E.

YOU CAN READ MORE ABOUT THI PROJECT IN THE LINK:

AND WATCH THE VIDEO:

NAVANTIA: AOR SEA TRAILS

ON AUGUST 7th, NAVANTIA DONE THE SEA TRAILS OF THE AOR SERIES LOGISTICS SUPPORT VESSEL FOR THE AUSTRALIAN NAVY.

THE FOLLOWING FERRI EQUIPMENT ARE INSTALLED ON BOARD:

-

-

-

- ELECTRO-HYDRAULIC FIXED BOOM CRANE FERRI SERIES F0 TN 200170 FOR GENERAL CARGO

- ELECTRO-HYDRAULIC FIXED BOOM CRANE FERRI F0 TN 050080 FOR GENERAL CARGO

- ELECTRO-HYDRAULIC FIXED BOOM CRANE FERRI SERIES F6 050080 FOR GENERAL CARGO, SOLAS AND AS LARS FOR THE INTERVENTION BOAT

- TWO MAN OVERBOARD RECOVERY DAVITS FERRI SERIES 2335 TN 1000

- TWO ACCOMMODATION LADERS FERRI SERIES 1819

-

-

NOR-SHIPPING 2019

FEINDEF-2019

L.A.R.S. FOR MEGAYACHT

WIND EUROPE-2019

COLOMBIAMAR 2019

EURONAVAL 2018 – PARIS

Innovative PYME

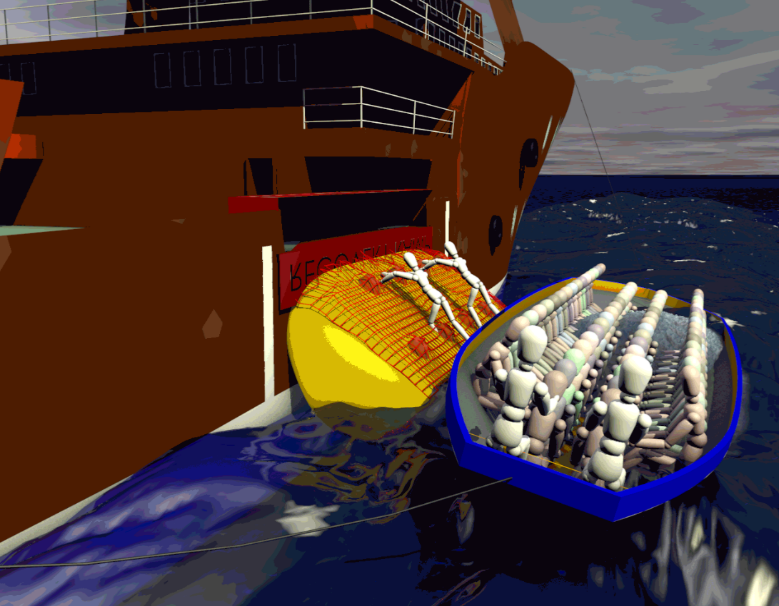

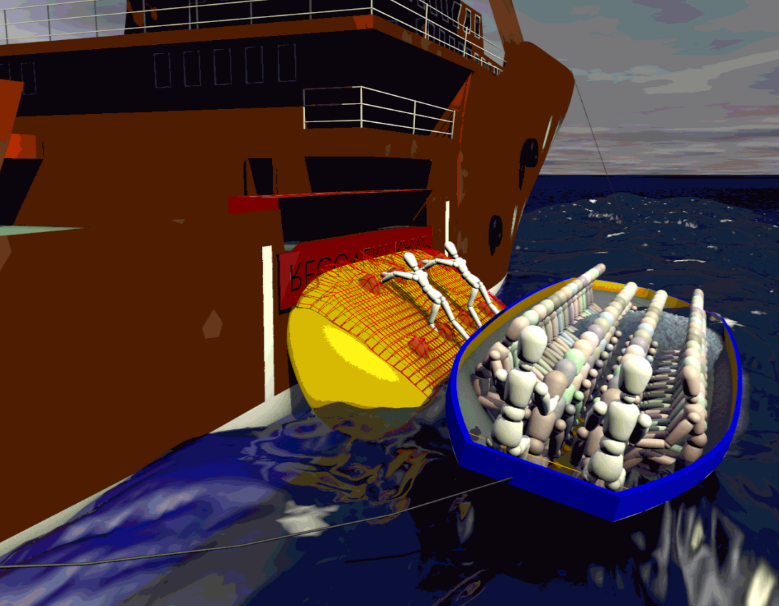

S.A.R.P.

It is a system developed and patented by Industrias FERRI, S.A., unique in the world, designed to improve the safety of people in the rescue of precarious vessels in the open sea. At this moment we are working on the manufacture of the first prototype.

The S.A.R.P. try to cushion the differences in movement between the lifeboat and the boat to ensure maximum safety for people and prevent accidents and drowning. It is installed on the side of the ship quickly and easily, and its operation is very simple. It develops in a short space of time, leaving one part submerged and the other on the surface. This will prevent the rescue boat from getting under the rescue boat acting as a defense and buffer between the two. Disembark easily from the boat, and access a rescue boat, as well as access from the water.

Development of a autonomous platform for vigilance and defence in offshore environments

Industrias FERRI S.A., leads the project Development of a autonomous platform for vigilance and defence in offshore environments, and The University of Vigo and Centre Internacional de Mètodes Numèrics en Enginyeria will cooperate too. The objective is the development of an autonomous reliable system for vigilancy operations in offshore environments capable to work in extreme sea conditions. Offshore environments is not only for wind farms and gas/petrol platforms, it is also for piracy areas, border areas, explosive or polluted atmospheares, etc.

This R&D project was approved by the Ministry of Economy and Competitivity, in coordination with Secretaría de Estado de Investigación, Desarrollo e Innovación, Secretaría General de Ciencia, Tecnología e Innovación, Dirección General de Innovación y Competitividad and Subdirección General de Colaboración Público-Privada the 29th of september of 2014 throught the Programa Estatal de Investigación, Desarrollo e Innovación Orientada a los Retos de la Sociedad, in the frame of Plan Estatal de Investigación Científica y Técnica y de Investigación 2013-2016.

Launching of the DISCOVERY, the most advanced oceanographic vessel in the world

As a successor to the world-famous English research vessel “James Cook”, the “Discovery” was launched on April 6. The vessel is being built by the Freire shipyard in Vigo and is for the National Environmental Research Council (NERC), UK.

In this project, INDUSTRIAS FERRI, S.A. is present to supply the main fore and aft cranes besides other lifting equipment for cargo movement onboard. Equipment assembly is already underway. Video of the launching operation: http://www.youtube.com/watch?v=cbjV6UWVc6E

Freire Shipyard http://www.freireshipyard.com/index.html

Tender support system for large vessels

The design, development and manufacture of a tender support system for large vessels

To design, develop and manufacture a hydraulic maintenance system, with a moderate cost, to facilitate launch and recovery operations (from port and starboard) to auxiliary people in large vessels.

High performance process for granite production

The design, development and manufacture of a new high-performance process for granite production based on continuous lathe cutting with diamond segments

To develop a new high-performance process for granite production (decreasing cut thickness by more than 60%) based on cutting with continuous metal lathe with diamond segments, reducing power consumption, and to create a demonstrator to test the new process.

Dynamic positioning equipment for large dredgers

The design, development and fabrication of dynamic positioning equipment for high capacity dredging vessels using a fairlead crane with anchor windlass

The design, development and manufacture of a special fairlead crane prototype for dynamic positioning large dredgers, able to withstand higher tensile stresses than those typically existing in the market, thanks to structural optimization of the whole.

Crude oil transfer device for vessels at sea

The design, development and manufacture of a device to transfer crude between tankers at sea

The design, development and manufacture of a mechanical device to be installed on oil tankers to enable the transfer of crude oil between these ships at sea, trying to make the operation as similar as possible to in-port operations.

Automated drill for marble and other ornamental rocks typical of cold areas or areas without water supply

The design, development and manufacture of automated equipment for extraction and cutting in quarries, in cold areas or areas with no water supply

To design a new drill for ornamental rock markets different to those catered for to date, demanding drilling machinery (marble, ornamental rock in cold areas or areas with no water supply) by adapting a drill for granite developed by Ferri and improving the quality of the process by increasing dilling performance.

LARS for marine research equipment

The design, development and manufacture of launch and recovery systems for marine research equipment

The design, development and manufacture of four prototypes (one telescopic crane and three A-frames) in order to acquire the necessary knowledge to incorporate LARS for marine research equipment to the Industrias Ferri catalog. The systems must satisfy the following requirements: high cost-load ratio and simple assembly/disassembly processes.